Hoses carrying demineralised water to cool electrical devices are critical to avoiding overheating and incurring unnecessary shutdowns.

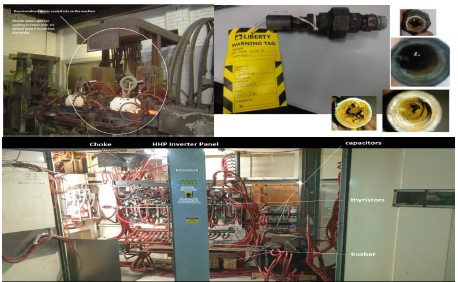

Following a recent shutdown of the Head Hardening Plant, it was revealed there had been a build-up of deposits in the closed water circuit.

To address this problem and ensure there is clean, unclogged pipework in the plant, the Steel Products team set in motion a comprehensive improvement was implemented, including using a corrosion inhibitor and solvents to dissolve deposits, introducing filter elements in the closed circuit and installing a large tank of demineralised water to avoid drawing down on potable water.

These preventative actions will reduce the chance of overheating and lost head hardened rails production.

Head hardened rails are typically used in metro rail projects and high-speed freight corridors. Head hardening technology needs a special heat treatment process requiring precise temperature control. It results in a 50 per cent higher hardness compared with a normal rail.